Various test methods

The reliability of cables that are constantly moved is substantiated with service tests, carried out in their practical conditions of use.

Test items

・Bend test

・Rolling bend test

・Torsional test

・Cable bear bend test

・Rolling bend test

・Torsional test

・Cable bear bend test

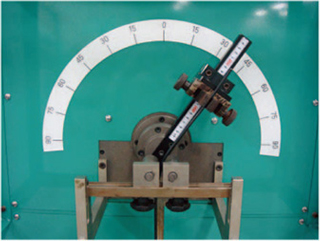

Bend test

- Objective

- To examine to what extent a cable can withstand flexing back and forth.

- Testing method

- Set the angle, speed, roll radius and load, and bend the cable back and forth.

- Judging method

- Based on the number of bend cycles at which the cable’s conductors completely break.

Torsional test

- Objective

- To examine to what extent a cable can withstand torsional flex.

- Testing method

- Set the length and load, and twist the cable by 90 degrees to right and left.

- Judging method

- Based on the number of twist cycles at which the cable’s conductors completely break.

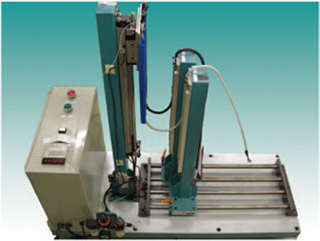

Rolling bend test

- Objective

- To examine to what extent a cable can withstand rolling bend (in the U-shape).

- Testing method

- Set the speed and the amount of bend, and roll the cable (in the U-shape) repeatedly.

- Judging method

- Based on the number of bend cycles at which the cable’s conductors completely break.

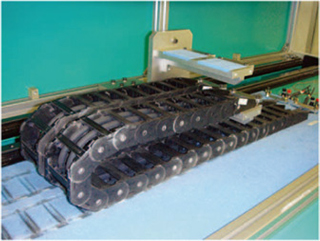

Cable bear flex test

- Objective

- To examine flex durability in a condition similar to practical implementation for robotic cables (FA cables), etc.

- Testing method

- Fit the cable in a cable bear and put it to traveling flex.

- Judging method

- Based on the number of bend cycles at which the cable's conductors completely break.

Flame test

- Vertical flame test

- Apply a flame to a vertically-positioned cable five times at a 15-second interval.

- Applicable safety standards

- UL 758, UL 158(1 UL VW-1)

CSA C22.2 No. 0.(3 CSA FT1) - Judging criteria

-

Cable not burning for more than 60 seconds after each flame exposure or label flag not burning at more than 25%.

Cotton fabric laid at the base not catching fire from cinders (other than FT1).

Cable bear flex test

Bend test

Rolling bend test

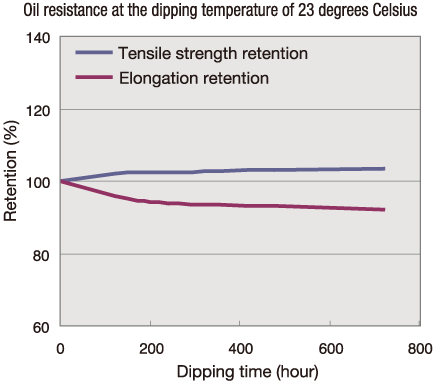

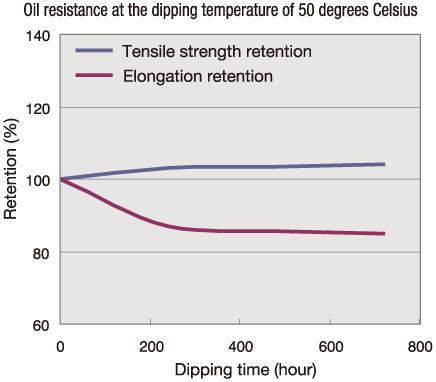

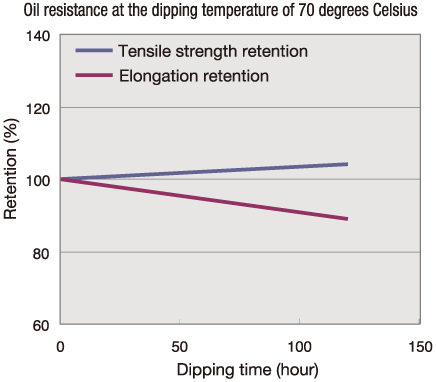

Oil resistance

Oil resistance test

- 1.Physical property tests

-

Test conditions

Test oil: Non-soluble cutting oil (Yushiron Cut DS50)

Dipping temperature: 23℃, 50℃, 70℃

- 2. Volume and mass

-

Test conditions

Test oil: Non-soluble cutting oil (Yushiron Cut DS50)

Dipping temperature: 23℃, 50℃, 70℃23℃ ×120h 23℃ ×240h 23℃ ×480h 23℃ ×720h 50℃ ×240h 50℃ ×480h 50℃ ×720h 70℃ ×120h Volume change(%) 5.31 5.84 2.75 6.39 1.02 -1.78 -1.52 -2.41 Weight change(%) 0.78 1.11 1.52 1.76 -1.00 -2.41 -4.15 -4.35 Judgment ○ ○ ○ ○ ○ ○ ○ ○ * The characteristic values are test data and not guaranteed figures.