HIGH SPEED CABLES, ASSEMBLIES (SINGLE-ENDED)

For internal wiring of communication devices and electronic devices. For connecting the test head and interface of the IC test system.

- Excellent stability of characteristic impedance and propagation delay time.

- Porous PTFE insulation provides an excellent temperature rating of -55℃~+200℃.

- It has excellent attenuation characteristics, and the braided shield type achieves -3dB/m at 6GHz.

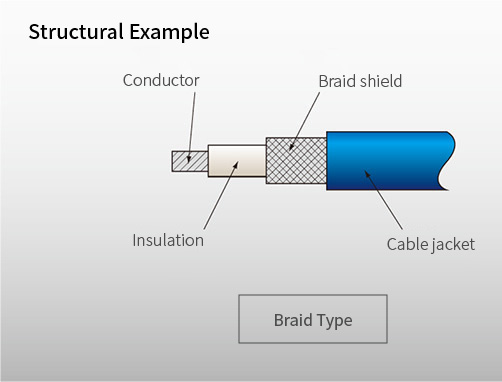

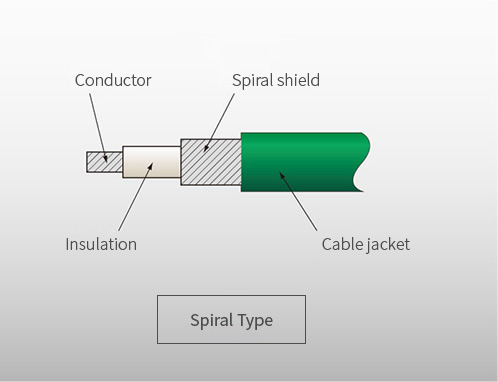

Structure and performance

| Item | Braid type | Horizontal winding type | |||||

|---|---|---|---|---|---|---|---|

| Conductor | Size(AWG) | 32 | 30 | 28 | 26 | 28 | |

| Configuration(pcs/mm) | 7/0.08 | 7/0.102 | 7/0.127 | 7/0.16 | 7/0.127 | ||

| Material | AGA | AGA | |||||

| Insulator | Material | E-PTFE+PFA | E-PTFE+PFA | FEP | |||

| Shield | Material | AGA | AGA | ||||

| Jacket | Material | FEP | ETFE | PFA | |||

| Outer diameter(mm) | 1.0 | 1.2 | 1.36 | 1.74 | 1.22 | 1.49 | |

| Impedance TDR(Ω) | 51±2.0 | 51±1.5 | 51±1.2 | 51±1.2 | 50±3.0 | ||

| Typical Propagation Delay Time TDR(ns/m) | 3.9 | 3.8 | 4.7 | ||||

| Standard capacitance 1kHz(pF/m) | 80 | 78 | 95 | ||||

| Standard attenuation | 0.1GHz(dB/m) | 0.56 | 0.45 | 0.37 | 0.30 | 0.39 | 0.40 |

| 0.4GHz(dB/m) | 1.12 | 0.91 | 0.76 | 0.62 | 0.80 | 0.82 | |

| 1.0GHz(dB/m) | 1.80 | 1.47 | 1.25 | 1.02 | 1.30 | 1.32 | |

| 2.0GHz(dB/m) | 2.61 | 2.15 | 1.83 | 1.51 | - | ||

| 3.0GHz(dB/m) | 3.26 | 2.69 | 2.31 | 1.92 | - | ||

| 6.0GHz(dB/m) | 4.81 | 4.02 | 3.47 | 2.93 | - | ||

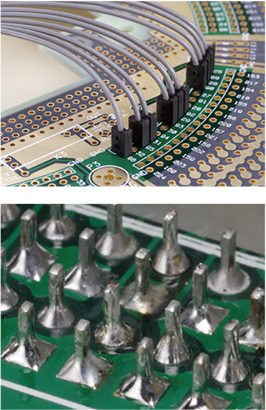

Hirakawa board-in cable series

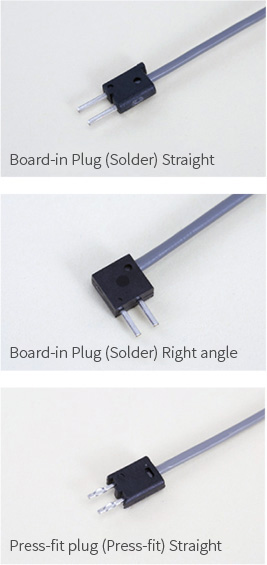

A cable connector assembly for board-to-board connection processed using original connection technology and molding.

It will be a tool to establish high-bandwidth transmission, high-density mounting, rationalization of wiring work, and improvement of connection reliability.

- 1. Flexible specification

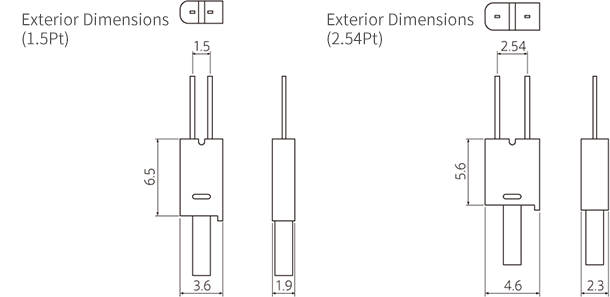

- Cables can be selected according to transmission characteristics such as impedance and propagation delay time, as well as length and color. We have a wide variety of standard plug pin shapes and lengths. (Non-standard products can also be designed according to your specifications.)

- 2. Excellent transmission characteristics

- Connections are made using dedicated equipment and processing methods, which are highly effective in stabilizing impedance/propagation delay time and reducing voltage loss.

- 3. Good mechanical properties

- The connection between the cable and the plug terminal is processed using our original electric welding technology, so it is not affected by the solder heat generated during the wiring work. In addition, the joints are integrally molded, so they are resistant to stress caused by bending. We will demonstrate outstanding connection reliability.

- 4. Two advantages: environmental friendliness and reduced man-hours

- The press-fit type that does not use solder can be inserted with a simple jig. At the same time, the work man-hours are greatly reduced.

Polarity display shape difference or mold surface core wire side ◯ Display

withstand voltage AC500V/1sec (between pins)

Insulation resistance DC500V/500MΩ or more (between pins)

Assembly example

Example of use

There are various coaxial assemblies other than those listed in this catalog, so please feel free to contact us.