High-precision, High-speed transmission cable

MULTI FLAT COAXIAL CABLES, ASSEMBLIES

Application

Internal and external wiring for large computers, IC testers, communication devices, and electronic equipment.

Features

- Stable propagation delay time and low skew are realized by our original highly foamed polyethylene extrusion technology.

- A thin coaxial cable is arranged in parallel, and only the terminal part is flattened.

- It is flexible and easy to mount and wire.

- UL standard products are available.

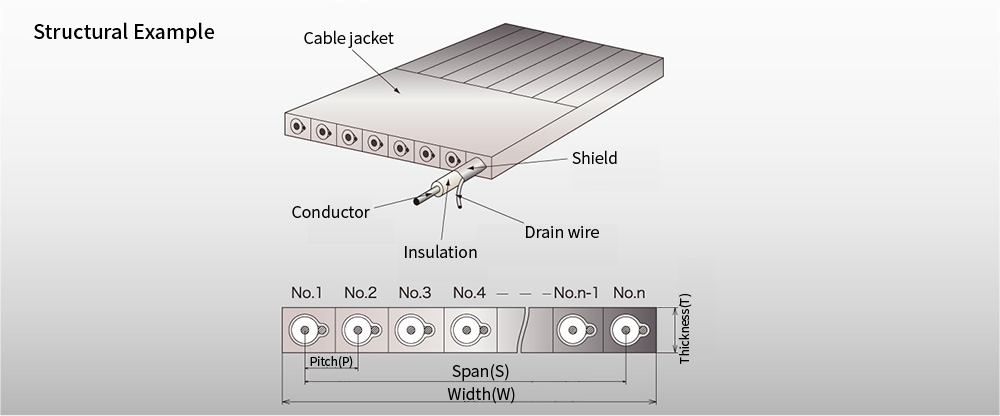

Structure and performance

| Item | 50Ω#34 | 50Ω#32 | 50Ω#30 | 50Ω#32 | |

|---|---|---|---|---|---|

| Conductor | Size (AWG) | 34 | 32 | 30 | 32 |

| Configuration (pcs/mm) | 1/0.18 | 1/0.203 | 1/0.254 | 1/0.203 | |

| Material | AGA | AGA | |||

| Insulator | Material | CCE | FEP | ||

| Drain wire | Material | AGA | AGA | ||

| Configuration (pcs/mm) | 1/0.18 | 1/0.203 | 1/0.254 | 1/0.203 | |

| Shield | Material | poly aluminum tape | poly aluminum tape | ||

| Jacket | Material | Lead-free PVC | Lead-free PVC | ||

| Size of fusion part | Pitch P(mm) | 1.00 | 1.27 | 1.27 | 1.27 |

| Span S(mm) | (number of cores - 1) x pitch P | (number of cores - 1) x pitch P | |||

| Thickness T(mm) | 0.76 | 0.95 | 1.05 | 1.10 | |

| Width W(mm) | Pitch P x number of cores | Pitch P x number of cores | |||

| Impedance TDR(Ω) | 50±5 | 50±5 | |||

| Typical Propagation Delay Time TDR(ns/m) | 3.78 | 3.80 | 3.70 | 4.70 | |

AGA: Silver-plated annealed copper wire, CCE: Polyethylene foam

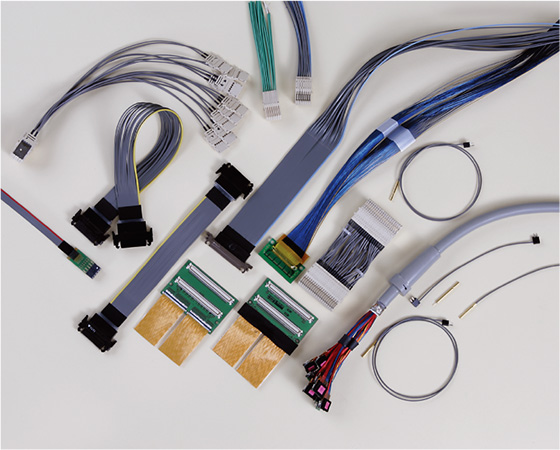

Hirakawa cable assembly

As a manufacturer that performs integrated manufacturing from cables to assemblies, we provide cable assemblies that meet the customer's required specifications and deliver 100% guaranteed products. Customers can use the connectors and cables as they are without the need for separate order management and acceptance inspections.

- 1.Compatible with various connectors

- In addition to the standard connectors of domestic and overseas connector manufacturers, we also design and manufacture customer connectors according to customer specifications.

- 2. Skew control

- Cable assembly with matching electrical length is possible. Of course, we also measure and guarantee the skew of finished products.

- 3. Original processing technology

- In addition to general cable processing equipment, we are making full use of our own equipment development and processing methods, so we can guarantee high connection reliability. In addition, we propose an assembly that reduces the initial cost and has good operability by using the integral molding technology that we have cultivated over many years.

- 4. Environmental measures

- In addition to lead-free specifications, we can also support various other environmentally friendly products. In addition, as a parts supplier, we are recognized as an eco-friendly partner by many customers.

Assembly example

There are various variations other than those listed in this catalog, so please feel free to contact us.