HIT-TUBE EG3

300V rated Heat shrink tube RoHS compliant

Application Standard

◎UL224, CSA C22.2 No.198.1: Flame-retardant grade VW-1

◎Electrical Appliance and Material Safety Law: Flame-retardant test (-F-) registration for insulated wires in equipment

Rating

300V, 125℃

(UL,CSA)

Color

black only

Marking (Example)

E221885 HIT-TUBE EG3 125C 300V VW-1 -F- TMR (Z) CSA

E221885 HIT-TUBE EG3 125C 300V VW-1 -F- TMR (Z) CSA

213977 HS XPO 125C 150V VW-1 * (Z) indicates dioxin countermeasure product

For insulation of electronic parts and electrical equipment, terminal processing of electronic processing, protection of mechanical properties of connection parts

- Heat-shrinkable tube with heat resistance and shape memory effect by cross-linking flame-retardant polyolefin by electron irradiation.

- Does not contain polybrominated biphenyls and polybrominated diphenyl ethers, which cause dioxins

| Characteristic item | Characteristic value | ||

|---|---|---|---|

| Electrical characteristics | Withstand voltage | before aging | AC 2.5kV/min No destruction |

| after aging | 158℃×168H C 2.5kV or more and residual rate 50% or more | ||

| breakdown voltage | before aging | AC 2.5kV or more | |

| after aging | 158℃×168H AC 2.5kV or more and residual rate 50% or more | ||

| specific volume resistance | 1014Ωcm or more | ||

| physical properties | Tensile strength | before aging | 10.4MPa or more |

| after aging | 158℃×168H 7.3MPa or more | ||

| stretch | before aging | 200% ore more | |

| after aging | 158℃×168H 100% ore more | ||

| Low temperature winding |

No cracks at -30℃×1H | ||

| heating winding | no cracks at 250℃×4H | ||

| chemical properties |

Combustion quality | Flame retardant, VW-1, -F- | |

| copper corrosive | Humidity 95%, 158°C x 168H after being left at 23°C x 24H No discoloration or corrosion of copper | ||

| copper stability | cHumidity 95%, Elongation 100% or more at 158°C x 168H after being left at 23°C x 24H | ||

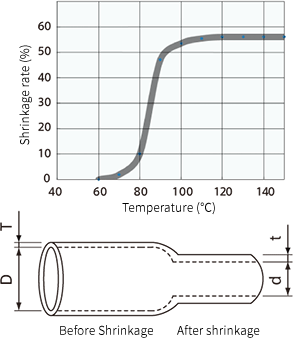

| Shrinkage properties | inner diameter shrinkage | over 50% | |

| longitudinal shrinkage | 10 % or less | ||

Shrinkage characteristics (reference)*3 minutes treatment in hot air

| Size(mm) | before contraction | After contraction(130°C×30 minutes) | Hirakawa part number | article length(m) | packing quantity(m) | Inner diameter D (mm) |

Standard thickness T (mm) |

Inner diameter d (mm) |

Part minimum thickness t (mm) |

Reel product | 1m item | Reel product | Reel product | 1m item |

|---|---|---|---|---|---|---|---|---|---|

| 0.8 | 1.25 | 0.10 | 0.40 or less | 0.180 | 9130-01 | 9130-51 | 200 | 2000 | 2000 |

| 1.0 | 1.40 | 0.50 or less | 9130-02 | 9130-52 | 1.5 | 1.90 | 0.75 or less | 9130-03 | 9130-53 |

| 2.0 | 2.40 | 0.15 | 0.95 or less | 9130-04 | 9130-54 | ||||

| 2.5 | 2.90 | 1.20 or less | 9130-05 | 9130-55 | |||||

| 3.0 | 3.40 | 1.45 or less | 9130-06 | 9130-56 | |||||

| 3.5 | 3.90 | 1.70 or less | 0.250 | 9130-07 | 9130-57 | 1000 | 1000 | ||

| 4.0 | 4.40 | 1.95 or less | 9130-08 | 9130-58 | |||||

| 5.0 | 5.40 | 2.40 or less | 9130-09 | 9130-59 | 100 | 500 | |||

| 6.0 | 6.45 | 2.90 or less | 9130-10 | 9130-60 | |||||

| 7.0 | 7.45 | 3.40 or less | 9130-11 | 9130-61 | 50 | 400 | 500 | ||

| 8.0 | 8.45 | 3.90 or less | 9130-12 | 9130-62 | |||||

| 9.0 | 9.445 | 4.40 or less | 9130-13 | 9130-63 | |||||

| 10.0 | 10.45 | 4.90 or less | 0.279 | 9130-14 | 9130-64 | 300 | |||

| 11.0 | 11.45 | 5.40 or less | 9130-15 | 9130-65 | 350 | ||||

| 12.0 | 12.45 | 0.20 | 5.90 or less | 9130-16 | 9130-66 | ||||