Wiring protection tube

HI-TUBE N

300V rated Non heat-shrinkable heat resistant vinyl tubing RoHS compliant

Application Standard

◎UL224, CSA C22.2 No.198.1: Flame-retardant grade VW-1 ◎Electrical Appliance and Material Safety Law: Flame-retardant test (-F-) registration for insulated wires in equipment

Rating

300V, 105℃

(UL,CSA)

Color

black, transparent

Marking (Example)

38522 HI-TUBE N 105C VW-1 -F- @ HIRAKAWA CSA

38522 HI-TUBE N 105C VW-1 -F- @ HIRAKAWA CSA

LR45507 PVC 105C 300V VW-1

Application

For insulation of live parts, protective insulation applied over primary insulation (double insulation configuration)

Features

- Non-shrinkable tube made of heat-resistant vinyl chloride

- Can be supplied in cut tube form

| Characteristic item | Characteristic value | ||

|---|---|---|---|

| Electrical characteristics | Withstand voltage | before aging | AC 2.5kV/min No destruction |

| after aging | 136℃×168H AC 2.5kV/min No damage | ||

| breakdown voltage | before aging | AC 2.5kV or more | |

| after aging | 136℃×168H AC 2.5kV or more and residual rate of 50% or more | ||

| specific volume resistance | 1010Ωcm ore more | ||

| physical properties | Tensile strength | before aging | 10.4MPa or more |

| after aging | 136℃×168H 7.3MPa or more | ||

| stretch | before aging | over 100 | |

| after aging | 138℃×168H 100% or more | ||

| Low temperature winding | No cracks at -30℃×1H | ||

| heating winding | No cracks at 180℃×4H | ||

| chemical properties | Combustion quality | Flame retardant, VW-1, -F- | |

| copper corrosive | Humidity 95%, 136℃ x 168H after being left at 23℃ x 24H No discoloration or corrosion of copper | ||

| copper stability | Humidity 95%, Elongation 100% or more at 136℃ x 168H after being left at 23℃ x 24H | ||

Note!

- ・Where the product is repeatedly bent

- ・Places subject to tension

- ・Places in contact with sharp edges of the chassis

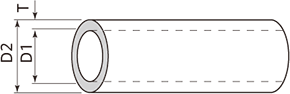

| Nominal sizeAWG | Inner diameter D1(mm) | Standard thickness T(mm) | Standard diameter D2(mm) | part number | unit length(m) | |

|---|---|---|---|---|---|---|

| HTV-2400T(black) | HTV-2100T(Transparent) | |||||

| 20 | 0.8 | 0.4 | 1.6 | 9152-03 | 9150-03 | 200 |

| 18 | 1.0 | 1.8 | 9152-04 | 9150-04 | ||

| 16 | 1.3 | 2.1 | 9152-05 | 9150-05 | ||

| 14 | 1.6 | 2.4 | 9152-06 | 9150-06 | ||

| 13 | 1.8 | 2.6 | 9152-07 | 9150-07 | ||

| 12 | 2.1 | 2.9 | 9152-08 | 9150-08 | ||

| 11 | 2.3 | 3.1 | 9152-09 | 9150-09 | ||

| 10 | 2.6 | 3.4 | 9152-10 | 9150-10 | ||

| 9 | 2.9 | 0.5 | 3.9 | 9152-11 | 9150-11 | |

| 8 | 3.3 | 4.3 | 9152-12 | 9150-12 | ||

| 7 | 3.7 | 4.7 | 9152-13 | 9150-13 | ||

| 6 | 4.1 | 5.1 | 9152-14 | 9150-14 | ||

| 5 | 4.6 | 5.6 | 9152-15 | 9150-15 | 100 | |

| 4 | 5.2 | 6.2 | 9152-16 | 9150-16 | ||

| 3 | 5.8 | 6.8 | 9152-17 | 9150-17 | ||

| 2 | 6.5 | 7.5 | 9152-18 | 9150-18 | ||

| 1 | 7.3 | 8.3 | 9152-19 | 9150-19 | ||

| 0 | 8.3 | 9.3 | 9152-20 | 9150-20 | ||